Hempcrete is an eco-friendly, forward-thinking building material that has been making headlines worldwide for all the right reasons.

However, despite the definitive proof of how well hempcrete works as a sustainable, eco-friendly material, the information surrounding it still needs to be improved. So we are here to help!

Unfortunately, due to the misinformation and myths that have spread surrounding hemp and cannabis, many of the fantastic benefits that hemp can offer have been forgotten.

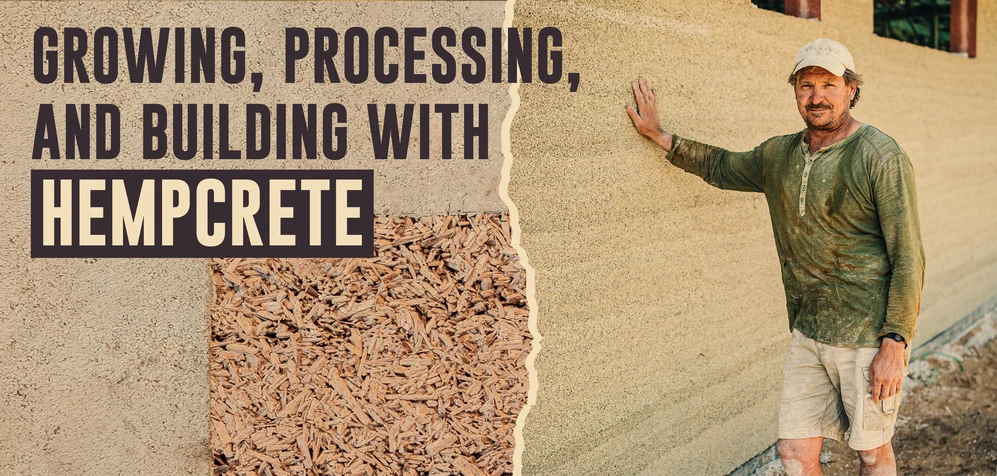

Hemp hurd is a product sourced from the hemp stalk's inner woody mass that can be found once the bast fibre has been removed. Technically speaking, this process makes hemp hurd a bi-product, but despite that, hemp hurd still has huge agricultural benefits for being low value.

You can read up on and learn more about hemp hurd here.

The first and most important step when planning to grow hemp for hemp hurd is to ensure that the seeds you have chosen are right for growing hemp hurd. Hemp is a multi-functional plant which means various seeds can have different benefits.

Next, it is vital that you check out the growing and licensing laws for hemp in your local area- especially surrounding the permitted THC content in the hemp plants. The last thing you want is to have acres and acres of good-quality, usable hemp and then realise that it is not permitted for growing or using by law.

Next, you will need to decide if you wish to plant a seed or a cone. A cone means working with known and stable genetics that will ensure you get the right crop for your hemp hurd and can save you money and time in the long run.

In comparison, seeds can often turn out as a different phenotype of quality than their parent and may not be fit for purpose.

Once your hemp plants are grown and ready for use, harvesting and processing will be next on your to-do list. Hemp benefits from being a fast-growing crop and is typically ready for use within 4 or 5 months - making it ideal for a fast turnaround rate!

Before harvesting, you will need to begin retting. The process of retting can be done in two different ways. One, you can let the dew work its magic naturally and wait for the hemp to be naturally retted.

Alternatively, you can soak the field and then wait for the hemp to dry. Doing this will allow the different microbial actions to separate the enzymes and bind to the inner woody stalks - making it easier and faster for you to separate the hemp stem.

Once retting is complete, the stalks are placed in a decorticator (an industrial machine that separates fibres and collects hurd), then dried and crushed. Once complete, you can gather your hemp hurd to stock up into bales or to start using!

Hempcrete is an eco-friendly, sustainable alternative to traditional concrete made entirely from hemp. In the past, hempcrete has not been used very often, but thanks to many of the concerns we now face in the modern world - hempcrete is quickly emerging as a solution!

However, turning hemp into hempcrete takes several steps and here are some of the top things to keep in mind:

Binding agents such as lime-based binders (50% lime, 50% metakaolin) can be used to make hempcrete. This type of binding agent works particularly well to absorb water and chemically cure the mixture while it is being made.

Lime-based binders are not the only type of binding agent that can be used to make hempcrete; clay and unrefined binders could also be used.

Mixing hempcrete can be done by hand or in a mortar mixer - it is that simple. While you are mixing, ingredients will need to be added one by one which goes in when it is really up to personal preference.

However, dumping the water directly into the hempcrete mix is the favoured method, as research seems to suggest.

Mixing hempcrete is surprisingly fast and should only take 10 minutes. Once the mixture starts to feel dry enough to retain shape but still moist - it is ready!

Hempcrete, like many other features of hemp, is multi-functional and has a huge amount of uses. Some of the popular ways to use hempcrete include:

Using hempcrete to build walls is one of the more common uses of hempcrete. This particular method is also known as the standard-slip form and requires you to cast the hempcrete in plastic or wooden structures and then tamp around the edges to secure it completely. This is a similar process to building walls with traditional concrete- except when it comes to hemp- casting is used.

Another very useful way of using hempcrete is by using it to build blocks. Hempcrete is a strong and durable material that creates the perfect recyclable, non-structural and ready-to-use building blocks. These blocks can then be used as the base for walls or other infrastructures.

Spray on hempcrete is quite literally what the name suggests – a hempcrete spray. This can be used to spray on walls in an industrial sprayer and offers a fast, convenient and affordable way to build walls.

The only downside to spraying on hempcrete is that equipment and knowledge are required to use it. However, as hempcrete rises, we are sure this will too!

As with all things hemp-based, hempcrete is also an extremely durable, versatile and eco-friendly material that offers a huge range and variety of benefits for anyone who chooses to use it.

For one, hempcrete offers a non-toxic, environmentally friendly way to build housing and other infrastructure without damage to nature! Read below to see a list of just some of the benefits of using hempcrete:

Unlike traditional building materials that can off-gas harmful chemicals, hempcrete is completely natural and non-toxic. This means a healthier living environment for you and your family.

Hempcrete is cost-effective in the long run. While the initial costs may be comparable to traditional materials, the energy savings over time make it a smart financial choice.

Hempcrete gains strength over time, making it a long-lasting alternative to traditional building materials. Its durability means less maintenance and a longer lifespan for your home.

Hempcrete has a unique combination of strength and flexibility, allowing it to withstand a variety of environmental conditions without compromising its structural integrity.

The thermal properties of hempcrete make it an excellent insulator, reducing the need for artificial heating and cooling systems, thus saving you money on energy bills.

Hempcrete actively absorbs carbon dioxide during its lifespan, making it a carbon-negative building material. This helps to combat climate change by reducing the overall carbon footprint of your home.

Hempcrete is naturally breathable, regulating moisture levels within the building and reducing the risk of mould and mildew.

The natural properties of hempcrete make it resistant to mould and pests, eliminating the need for chemical treatments.

At the end of its life cycle, hempcrete can be recycled, contributing to a more sustainable and circular economy.

Hempcrete is naturally fire-resistant, providing an extra layer of safety in areas prone to wildfires.

Not only that, but hempcrete (similarly to hemp plants) also works to absorb C02 as well as other irritants from the atmosphere - making your home or building have cleaner air. Hempcrete can also work as a natural way to easily regulate the temperature inside the building, thanks to hemp's thermal properties.

The toll the modern world has taken on our planet over the last few years is becoming more obvious, with frequent insane weather patterns and natural disasters becoming a normal, regular occurrence.

Switching to more eco-friendly building materials like hempcrete is just one way to reduce the planet's overall carbon footprint and take a step toward healing our beautiful planet.