Surely you’ve heard by now - Hemp textiles are making a huge comeback in fashion and industry! As one of the first fibres ever documented to be used by mankind, it’s no surprise to us that the pullback was short-lived.

You can only imagine how different society would be if it wasn’t made illegal for so long! But hey, that’s history now, and we’re finally reestablishing our relationship with civilization’s oldest agricultural companion.

While Hemp is known for its speedy growth, various commercial applications & diverse benefits to the environment, the benefits you will see by choosing Hemp are often overlooked - and good for you! That means you’re already thinking about the environment over yourself.

But this article is dedicated to you - the reader, supporter, and enthusiast of all things hemp. We’re going to tell you all about how you benefit from choosing Hemp textiles, what sorts of products can be made & how, the history of Hemp textiles, and then look at a few incredible Australian fashion designers who are making waves with their handmade Hemp clothing options.

Let’s get into it!

If you're here reading this, chances are you've searched for something to do with Hemp fabric. If you're researching the benefits of Hemp textiles, we've gone ahead and gathered some of the common key points & the research behind them.

Keep in mind that more research should still be done, as much of this data was only confirmed by singular studies. We hope to see more investigations as the industry develops and begins to demand more attention!

Here are 8 incredible benefits you'll be wearing by choosing Hemp fabric.

UV resistance is the first of many benefits we’ll touch on. Research has shown undyed Hemp fibres to have a naturally occurring UV resistance to the factor of 33-50, which is considered very good to excellent UV protection.

Fibrous plants such as Hemp have been studied in-depth for decades, and researchers have found that among many things, the lignin content of the plant offers resistance to many common bacterial pathogens. Additionally, Hemp is moisture-wicking (which we’ll touch more on later) which means that it’s resistant to mould and fungal growth.

If the manufacturers wish to take the route of mechanical processing, absolutely no chemicals are required to make the clothing. After the process of retting, and then the separation of fibre from the bast, mechanical decortication can clean the fibres and prepare them to be spun into Hemp yarn.

We’ll break down this process further later in the blog. However, it’s also important to note that countries like China are fond of chemical-based processing due to it being easier to achieve a cotton-like output.

The fibres of Hemp are hollow in formation, which provides natural insulation to clothing & apparel made from it. While this is going to be most impactful on livestock and construction, those seeking inter-seasonal clothing options can look to Hemp as a solution.

This is just one of such benefits that makes Hemp the perfect choice for long-term wardrobe selection.

These two characteristics of Hemp fibre are what give the textiles their superior strength. Tensile strength is defined as stress measured as a force per unit area and suggests how much stress a material can take before breaking.

The strength-to-weight ratio is a similar measurement that proves how much weight can be held by a certain amount of fibre in question. Some diameters of Hemp have even been shown to be stronger than some types of steel!

The hollow fibres in Hemp also encourage a high rate of moisture absorption and dissipation - also known as moisture-wicking properties. This makes it an excellent choice for activewear, workwear, and general day-to-day activities. From sweat to spills, Hemp will readily absorb and evaporate the liquid.

Of course, we can’t speak for coffee stains (keep it clear!)

Hemp is a positive choice due to the potential for reuse, repurposing, and (eventually) responsible discarding. At the end of your Hemp clothing item’s life, you can repurpose it in areas like the garden before discarding it fully. In fact, you can even compost Hemp textiles if natural processes were used in manufacturing!

Clothing and apparel made from Hemp can confidently withstand the test of time. It holds shape and colour marvellously well, whilst still maintaining its structural integrity.

Additionally, as you wear it and wash it the Hemp fibres will continue to smooth and get softer over the years you wear it. And again, it won’t lose strength in that process! Yet another reason that Hemp can lead the way in our battle against fast fashion trends.

Manufacturing Hemp textiles was a specialty of societies around the world for thousands of years. Unfortunately, the result of prohibiting cannabis was much of the world lost most of their knowledge.

Certain countries around the world continued to grow Hemp for textiles all throughout the "war on cannabis", and unsurprisingly, these countries are now leading the industry and have a huge advantage over the rest of the world.

Even though the world has been making Hemp textiles for a long time, the processes have remained quite similar - apart from the increase in technology. The ultimate idea is to remove the fibres from the stalk and turn them into yarn through processing. Let's take a look at how it works!

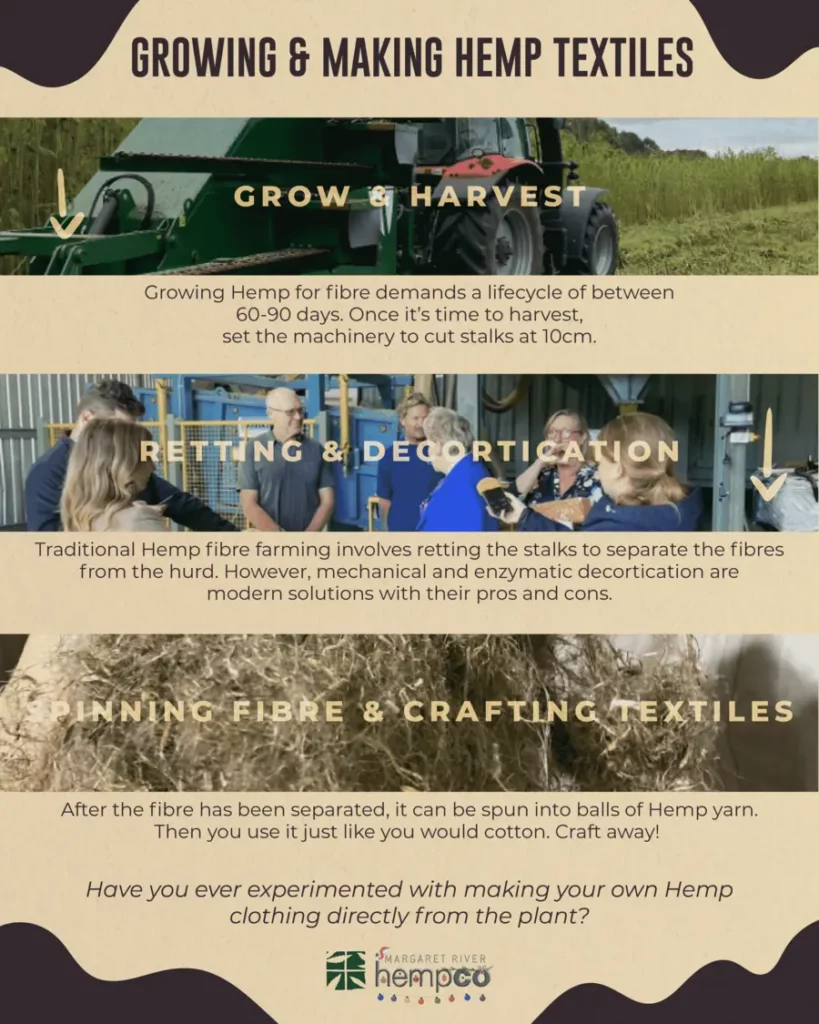

The first step in making Hemp textiles is the most obvious - growing & harvesting Hemp. Depending on what you’re farming for, you will want to harvest at different points - and it’s important to know when!

When farming for fibre, you’ll want to harvest between 9 and 12 weeks depending on the variety you’re growing. It’s best to consult your genetics supplier before starting your crop to ensure your variety is optimal for fibre growth.

Once your crop is ready, you’ll want to cut from 10cm above the stalk. You’ll be able to program this setting on any decent harvesting equipment.

After the hurd is harvested, there are a few ways to go about separating the fibre from the stalk. The first one is through retting, which is a natural enzymatic process that occurs when Hemp is left out to battle the natural elements.

Moisture and light work in synchronicity with the microbiome of the soil to naturally separate the fibres from the stalk, resulting in easy-to-remove fibre strips that can be decorticated & spun into yarn. There are also mechanical processes that can substitute retting.

Each way produces a different quality of fibre, so it’s worth consulting with professionals before deciding on your best course of action.

It’s also worth mentioning there are unnatural, chemical-based methods of separating the fibre from the stalk that results in much softer textiles. Unfortunately, this ruins the magic of Hemp being an eco-friendly clothing option.

After decorticating your raw Hemp to remove the harsher fibres, you’ll be left with raw Hemp fibre that can be spun into balls of yarn. Much like cotton, this yarn can then be used to weave any piece of apparel you want.

Humans have been perfecting these techniques for thousands, even tens of thousands of years. How much do you know about the history of Hemp textiles? Read on for a quick rundown!

Pretty cool, huh?

The oldest strand of Hemp textiles has been dated back to over 20,000 years to the neolithic area, in the geographical area where the Gravettians, a trap and net hunting civilisation were known to live. It’s speculated that they used Hemp fibre in their nets as the imprints from an excavation resembled the makeup of Hemp fibres.

Hemp fabric remnants dated back 8000 years have been excavated in the Mesopotamia region, which is located in the Middle East. This is the oldest known preserved remnant of ancient Hemp fabrics and demonstrates the progress in agricultural practises that our race made between 20,000BC and 6,000BC.

Slightly more recent was the writings of the Greek historian Herodotus, who described the Hemp fabric as being used by the Dacians and Thracians around 5000 years ago. The area now known as Romania has been the home to a range of historical artifacts uncovered that show us how Hemp was used in ancient days, including a ritualistic artifact containing Hemp seed.

For thousands of years, nations around the world continued to develop new Hemp farming and processing techniques to service a rapidly growing population. Hemp textiles were the most common fibrous commodity on earth for thousands of years

Hemp maintained dominance over the textile market and was a key resource in the age of sail. Garments and sails for ships were the primary use for the fibre.

This continued until the 1930s when the U.S began to disavow the very plant that allowed America to be founded - cannabis. The disavowment was short-lived as the U.S government ran a campaign called ‘Hemp For Victory’ to encourage farmers to grow Hemp for resources in WWII. The government insisted it was a farmer’s patriotic duty. George Bush Sr. himself was actually saved by a Hemp parachute during this war.

After WWII, prohibition was reinstated and Hemp production all but ceased for a few decades. Much of the world followed, minus a few countries like Romania, India, and China who continued to refine manufacturing techniques for, and produce Hemp textiles.

As of this year (2021) we’ve seen a significant resurgence of interest in Hemp textiles, and cannot wait to see how modern technology can be applied to this space. Read about some of the emerging Hemp textile tech here!

Anything that can be made from cotton, polyester, timber, bamboo, or linen can also be made from Hemp. It’s actually more sustainable, more durable, and healthier for the wearer, which begs to question why we ever stopped using it in the first place (but read on to the history of Hemp fabric and learn why we did).

If your creativity isn’t already getting the best of you, here are some examples of clothing & apparel you can make with Hemp.

Whilst the manufacturing and distribution of such items are generally left to larger brands that have factories, retail outlets, and other distributors, there are also some remarkable options for customised, designer clothing made from Hemp.

From high-end fashion to bohemian-style beachwear, Hemp & Hemp blends also offer versatility and practicality in niche sectors in a fashion that can’t be ignored! Fortunately for us, Australia is home to some of the best seamstresses and designers the Hemp industry has. Let’s take a look at some!

Clearwater Designs offers gorgeous bohemian-style clothing & apparel that’s handcrafted from the Hemp fabric we supply!

The enigmatic yet lighthearted cuts & patterns in these styles are complemented by the ever-changing, unique textures of Hemp. Head over to their Instagram to check out their work!

Jess, of Wildly Weaved (Instagram), is an expert in her craft. We’ve been fortunate enough to be her Hemp fabric supplier for quite some time now.

Seeing the continual quality improvements & regular new additions to her range have been very encouraging, and sets the bar high for aspiring designers - Whether they use Hemp or not! From summer steeze to winter warmers, Jess is both skilled & passionate when it comes to working with Hemp.

Check out her Etsy store here!

Leah Kelly has made waves this year, specifically with her showcase at the 2021 London Fashion show that we saw in September!

Coming straight out of WA, Leah specialises in working indigenous Australian themes and styles into outstanding fashion statements for just about any high-occasion you could think of. Weddings, formals, or functions - you name it, she’s probably done it!

Coming through with over 20 years of experience, a passion for sustainability, and appearances on some of the most prestigious runways on earth, it’s safe to say that Leah is one of the best in Australia, and among the most skilled in the world.

Yes! It most certainly is. In fact, it could be argued that Hemp fabric is the most sustainable choice on earth when it comes to materials for clothing & apparel. Growing Hemp is great for the earth due to its functions of bioremediation and carbon sequestration.

Farming Hemp for industrial uses is carbon-neutral at the least, and carbon-positive when done right. This means it removes as much or more Co2 from the atmosphere as the products that will be made from it will release.

Additionally, leaf fall and biomass infuse nitrogen back into the soil. This makes Hemp ideal for crop rotations because it is revitalising the soil for the next crop.

The deep taproot also keeps soil turning up, so it’s easy for the next crop to develop roots and soil remains fresh.

So now you know!

Know what?

Well, just about everything there is to know about Hemp textiles. That's the lot. It's quite simple once you wrap your head around it. If you know the processes, benefits, and uses, you have a good enough idea to start dreaming. What is your dream Hemp garment?

Chances are it's already been done, but if it hasn't, maybe it's time to look into starting your own Hemp textile-based business. And even if it is done, it could be worth looking into - the more, the merrier! We'd love to help you choose & purchase your very own Hemp fabric for your brainchild.

If there's anything else you'd like to know, please do reach out!